Dec 10, 2025

Grading doesn’t fall behind because crews aren’t working hard. It falls behind because older methods slow everything down. Staking takes time. Grade checks take time. Fixing low spots takes even more time. GPS machine control changes that. By guiding equipment with satellite signals and a 3D model, it removes most of the delays that normally stretch a grading schedule.

Here’s how modern GPS machine control, including systems like Topcon MC-X, cuts grading time nearly in half while improving accuracy and reducing rework.

How GPS Machine Control Works

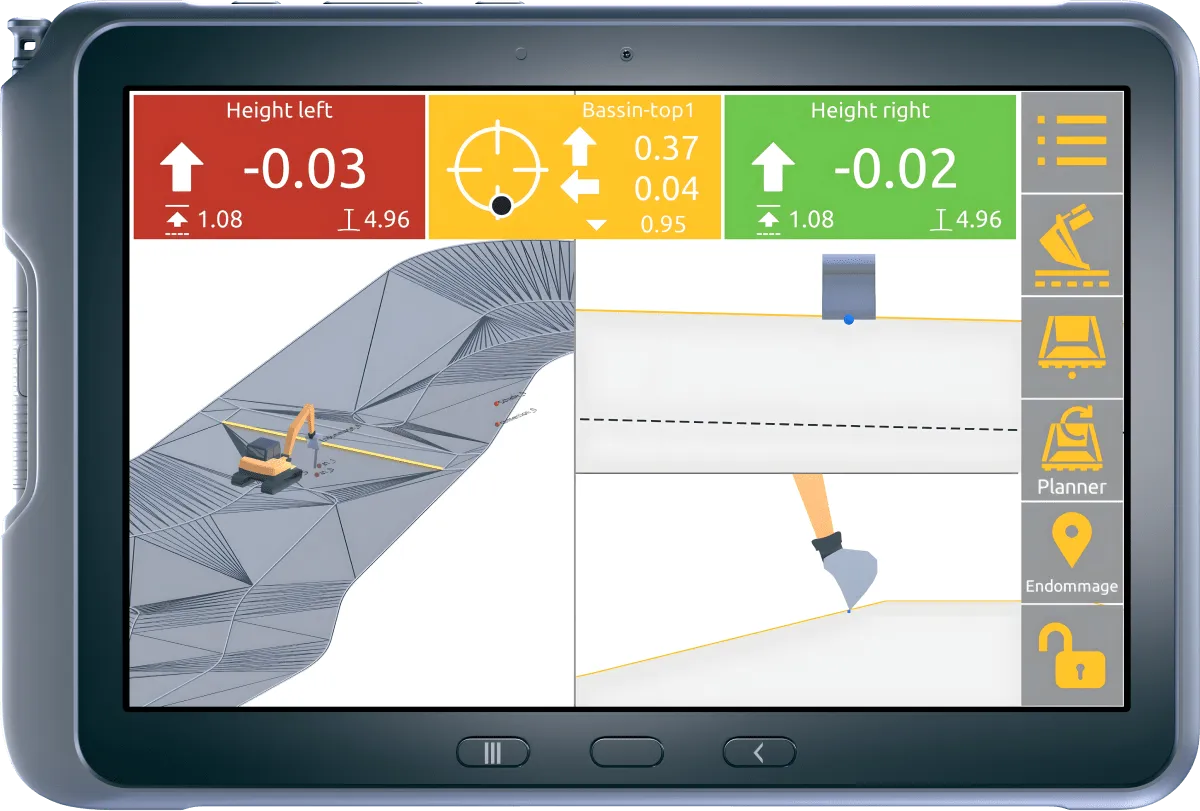

GPS machine control uses GNSS satellite signals, a base station, and a 3D digital site model to guide dozers, graders, and excavators in real time. Instead of relying on stakes or guesswork, the operator sees the design surface on a screen inside the cab.

A typical setup includes:

Topcon GNSS antennas and receivers mounted on the machine

In-cab controls such as the Topcon GX-55 display

A rover for on-foot grade checks

A 3D model that shows all design elevations, slopes, crowns, and base depths

This setup allows the operator to place the blade accurately without stopping for layout or waiting on survey crews.

How the GPS System Guides Earthwork Equipment

1. Build the 3D Site Model

The project begins with a 3D model built from survey data. This includes subgrade depths, base thickness, ditch lines, driveway crowns, building pad elevations, and stormwater slopes.

2. Load the Model Into the Machine

The digital model is transferred to the dozer, grader, or excavator. The operator can view cut and fill values on the display and follow the exact design grade.

3. GNSS Base Station and Satellites

A base station broadcasts correction signals to the machine, improving accuracy to a centimeter-level range. This process is known as RTK (Real-Time Kinematic) correction.

4. Automatic or Semi-Automatic Blade Control

The machine adjusts the blade or bucket to match the design surface. Operators can focus on safe, smooth operation rather than chasing grade.

5. Verification With a Rover

A rover can check any point on the site to verify subgrade, drainage slopes, and fine grade without relying on stakes.

Why It Cuts Grading Time in Half

GPS machine control dramatically speeds up production by removing the most common sources of delay.

Minimal Staking

Traditional staking requires multiple survey visits and frequent resets. GPS grading eliminates the majority of staking, allowing work to begin right away.

Fewer Passes to Hit Grade

The machine displays exact cut and fill information. Operators avoid over-excavating or overfilling, and final passes require far less correction.

No Waiting on Survey Layouts

Crews can work continuously. Any design adjustment is updated digitally rather than through physical re-staking.

Less Rework

Accurate slopes, elevations, and base depths reduce callbacks and help projects pass inspections on the first attempt.

Faster Fine Grading

This is one of the largest time-savers. Reaching final grade accurately the first time speeds the handoff to paving, concrete, or utility crews.

Traditional Grading vs. GPS Machine Control

Task | Traditional Method | GPS Machine Control |

Layout and staking | Multiple survey trips | Minimal or none needed |

Rough grading | Several passes required | Fewer passes |

Fine grading | High chance of rework | Often correct on the first pass |

Checking grade | Crew with hand levels | On-screen, immediate |

Drainage accuracy | Depends on operator skill | Matches exact slope in the model |

Total timeline | Slower with more interruptions | Often 40 to 60 percent faster |

Where GPS Machine Control Has the Biggest Impact

Roadway Prep and Base Work

Long stretches of subgrade and base rock benefit the most. Crowns, cross-slope, and base depth can be cut accurately on the first attempt, improving the transition to paving.

Gravel Driveways and Private Roads

On long driveways or access roads, GPS ensures consistent drainage, an even crown, and a smooth travel surface. This significantly reduces rework caused by low areas or standing water.

Building Pads and Commercial Pads

Accurate pad elevation prevents issues with doors, foundations, and flatwork. GPS also speeds up base rock placement by avoiding overfills.

Pond Excavation and Reclamation

GPS guidance helps achieve:

Designed pond depth

Dam and berm elevations

Proper spillway grading

Safe and stable side slopes

Accuracy Benefits That Support the Time Savings

Speed is important, but accuracy is what prevents delays later in the project. GPS machine control keeps subgrade and base rock within the correct depth, shapes drainage slopes cleanly, and holds tie-in elevations around structures and curbs. Because the blade follows the 3D design surface, material is placed more consistently and waste is reduced. This level of accuracy limits rework, lowers the chance of failed inspections, and keeps the schedule moving without unexpected corrections.

Cost Savings That Come With Faster Production

GPS machine control also reduces overall grading costs. Crews spend less time staking, checking grade, and making extra passes, which lowers labor and machine hours. Fuel use drops, and material waste is reduced because cuts and fills are more accurate. Survey visits become less frequent, and there is far less rework from incorrect elevations. When grading is completed accurately on the first attempt, every trade that follows can start sooner, creating savings across the entire project timeline.

GPS Machine Control FAQs

Ready for GPS-Accurate Grading on Your Project?

If you need roadway prep, driveway construction, pond excavation, or site grading in the Kansas City metro, GPS machine control helps deliver faster schedules and accurate final grades. Get a Free Site Visit & Quote to see how precise digital grading can improve your project.